In February, a tow-pages article was dedicated to our EXOCOAT™ Ceramic+ in Jachtbouw Nederland Magazine.

See below the translation into English

Infinite Shine

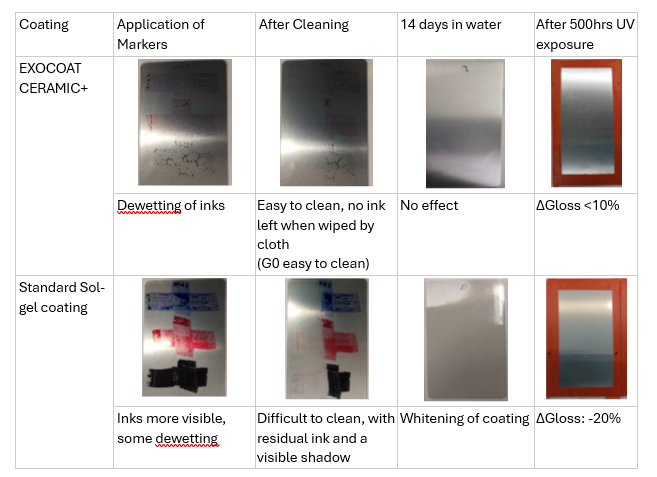

The ceramic coating Exocoat Ceramic+ by Axcentive makes hull maintenance more sustainable, saves costs, delays the need for refitting, and reduces CO2 emissions. A thickness of just two microns is enough to keep the hull above water gleaming for years.

Axcentive originates from a management buy-out of Akzo in 2004. “For the past 10 years, we have been developing ceramic coatings,” says Marco van de Pol from Axcentive. “Exocoat Ceramic+ is our most recent product and offers many advantages over what is currently available on the market.” His colleague Arno Schut adds: “The coatings are based on chemical science, in which both Marco and I are trained. Extensive research and practical experiences in America and Southern Europe show that our ceramic coating does exactly what it’s designed to do.”

Easy and cost-effective

“When a large yacht undergoes a refit, which is typically needed once every five years, the hull is sanded, filled, and repainted,” says Marco van de Pol. “These tasks are time-consuming, CO2-emitting, and expensive. With our Exocoat Ceramic+, you can delay such a refit by two years or longer. You only need 10 milliliters per square meter on a cleaned surface for optimal protection and shine again. Our coating is a single-component product, making it easy to apply. For large ships, you spray it on, and for smaller ones, you apply it with a microfiber sponge. It’s liquid when applied and dries in the air. Let’s say a hull refit costs 1 million euros; with a treatment using Exocoat Ceramic+, you’ll only spend 100,000 euros.”

Long-lasting shine

“A layer of Exocoat Ceramic+ maintains its shine for two to three years, after which you can repeat the process,” says Arno Schut. “Technically, you can apply a new layer every three years indefinitely, except when there are damages to the hull. Our coating is as hard as glass, or better yet, as hard and strong as diamond, which contributes to the long-lasting shine. A thickness of two microns keeps the layer flexible, allowing it to adhere well to the surface. Exocoat Ceramic+ forms a chemical bond with the substrate without damaging it. The layer does wear down slowly, but what enters the environment is silica, or sand. This waste stream is therefore not harmful to the environment.”

Innovative

The glass-hard ceramic layer is super smooth, water-repellent, UV-resistant, self-cleaning, scratch-resistant, dirt-repellent, and maintains its shine for years. “I have seen it many times in practice, such as on superyachts in Florida, so I know it’s not too good to be true,” says Marco van de Pol. “This is exactly what our coating does, making it a welcome addition to existing coating systems. The market still needs to get used to the new revolution of ceramic coating in some cases. We already apply this technology extensively on yachts, as well as on cars and other coated parts, with the primary goal of extending maintenance intervals. This significantly reduces costs and environmental emissions.”

In addition to coatings for coated parts, Axcentive also offers special ceramic coatings for glass (super water-repellent) and exhausts (dirt and soot-repellent). These ceramic coatings are also applied to yachts. For the Benelux region, Van Dongen Verf is our partner, and starting this spring, the coating will be available through shipyards and retail.